Continuous Mixer

m-tec® Continuous Mixer: Perfected for Modern Construction Sites

Innovative Mixers for Dry Mortar: m-tec® Continuous Mixers are specifically designed for the processing of traditional dry mortar products and optimized for the demands of modern construction sites. They offer flexible applications tailored to various use cases and grain sizes.

Versatile Loading Options: Our continuous mixers can be fed with both bagged material and silos, allowing them to fit seamlessly into any workflow. This versatility allows for efficient adaptation to the specific needs of each construction site.

User-Friendly Design:

- Intuitive Controls: The clear layout of the controls and the deliberate omission of unnecessary switches make operation easy.

- Quick-Change Systems: m-tec®'s signature easy-to-use closure systems allow key components such as the mixing tube or mixer motor to be changed quickly, significantly reducing maintenance time.

Excellent Mixing Properties: m-tec® continuous mixers are renowned for their excellent mixing performance, ensuring consistently high quality of the mixed material. Their design also facilitates cleaning, allowing the mixer to be quickly ready for the next job.

Efficiency and Performance: m-tec® continuous mixers are designed to increase productivity and reduce labor effort. They are the ideal solution for efficient and clean work on the construction site.

Explore our extensive range and choose the ideal mixer for your jobsite needs.

m-tec® Continuous Mixer flotti: Ideal for Small Batches and Easy Handling

Overview: The m-tec® flotti is specifically designed for processing small batches from bags and features a powerful 230V motor that allows operation with standard household power outlets. Its simple design allows for easy cleaning, making it ideal for quick deployment.

Applications: The flotti is perfect for a variety of dry mortar products, including plasters and self-leveling compounds, providing flexibility for different construction site requirements.

Standard Equipment: The flotti comes equipped with a mixer motor, water fittings, and transport and mixing shafts.

Accessories: An optional material hopper cover is available for added protection and cleanliness when not in use.

Key Features and Benefits:

- Intuitive Operation: Clear and simple control elements, with no unnecessary switches, make operation easy.

- Quick Component Change: m-tec®'s typical closure systems enable quick changes of essential components, such as the mixing tube.

- Plug & Work: The flotti is quickly ready to use and easy to clean, thanks to its simple setup and standard Schuko plug connection.

- Durability: Robust steel construction ensures a long service life and simplifies maintenance work.

m-tec® – Technology for Better Building: m-tec® develops and manufactures construction site technology for both traditional and modern construction needs, and drives innovative technologies such as 3D concrete printing. With products in nearly 100 countries worldwide, m-tec® sets the standard for efficient and economical construction.

Technical Data

| flotti |

Flow Rate: | approx. 20 l/min |

Drive Motor: | 1,3 kW, 230 V, 50 Hz |

Electrical Connection: | 230 V, 50 Hz, 1 ph |

Fuse: | 10 A |

Power Cable: | 3 x 2,5 mm² |

Plug: | Schuko |

Water Connection: | 1/2" water hose with GEKA coupling, required water pressure: min. 2.5 bar during operation |

Dimensions: | approx. 1400 x 500 x 1000 mm |

Weight: | approx. 90 kg |

Conveying capacity, range, and height depend on the material being conveyed, as well as the selected stator and rotor.

You can download our brochure as a PDF here.

m-tec® Continuous Mixer D10: Versatility and Efficiency for Your Construction Site

An overview: The m-tec® D10 is specially designed for processing traditional dry mortar products with a grain size of up to 4 mm and fine-grained products with a high plastic content, such as adhesives, embedding and levelling compounds or dry plastic, silicate or silicone plasters. This makes it a versatile tool for various applications on modern construction sites.

Applications: The D10 is ideal for a wide range of dry mortar products, including plasters and self-leveling compounds, and offers high flexibility for use in a variety of conditions.

Standard Equipment: The standard package includes the continuous mixer with mixing motor, water fittings, homogenizing section, control unit, feed screw, and mixing shaft.

Accessories: Optional accessories such as a dry material sensor or a stand with a feed hopper are available to customize the mixer for specific job site requirements.

Key Features and Benefits:

- User-Friendly: Intuitive operation with a clear layout of controls and the omission of unnecessary switches. Easily manageable closure systems facilitate quick changes of key components such as the mixing tube.

- Cleaning: The use of PU components simplifies cleaning and minimizes material buildup, resulting in quick and thorough cleaning.

- Mixing Quality: Consistently high mixing quality due to long mixing times and the m-tec patented wetting principle.

m-tec® – Technology for Better Building: m-tec® develops and manufactures construction site technology not only for traditional applications but also for the challenges of modern construction sites. With products in nearly 100 countries worldwide, we set standards for faster, safer, and more economical construction.

Technical Data

| D10 |

Flow Rate: | Standard approx. 15 l/min (depending on transport and mixing shaft) |

Drive Motor: | 2,2 kW, 230/400 V, 50 Hz |

Electrical Connection: | 230/400 V, 50 Hz, 1/3 ph |

Fuse: | 16/10 A |

Power Cable: | 3 x 2,5 mm²/5 x 1,5mm² |

Plug: | Schuko/16 A, 5p, 6h |

Water Connection: | 3/4" water hose with GEKA coupling, required water pressure: min. 2.5 bar during operation |

Dimensions: | approx. 1700 x 440 x 470 mm |

Weight: | approx. 85 kg |

You can download our brochure as a PDF here.

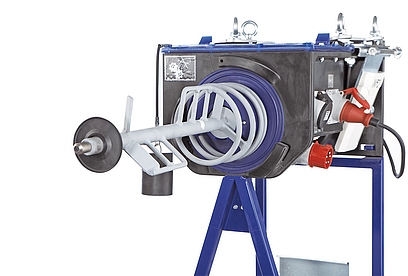

m-tec® Continuous Mixer D20: Robustness and Versatility for Your Construction Site

Overview: The m-tec® D20 is a robust all-rounder designed for processing dry mortar products up to a grain size of 4 mm. As the best-selling mixer in its class, it streamlines the handling of various materials such as ETICS adhesives, decorative plasters, masonry mortars, or fine concrete.

Applications: The D20 is ideal for a wide range of dry mortar products, including plasters and self-leveling compounds, making it an indispensable tool on any construction site.

Standard Equipment: The standard package includes the continuous mixer with mixing motor, water fittings, transport screw, and mixing shaft.

Accessories: Optional accessories include a water pump or a cover for the material container to enhance efficiency and cleanliness during use.

Key Features and Benefits:

- Versatile Versions: The 230V version is specially optimized for processing decorative plasters, while the 400V version is ideal for heavier materials such as masonry mortar or fine concrete, thanks to its ball-bearing concrete mixing tube.

- User-Friendly: Clear and simple control elements, as well as easy disassembly and maintenance, ensure hassle-free handling of the D20.

- Durability and Longevity: Robust steel construction ensures long service life and facilitates maintenance work.

Plug & Work: The mixer can be operated with standard Schuko sockets thanks to its 230V motor, and its simple design allows for quick and thorough cleaning.

m-tec® – Technology for Better Building: m-tec® develops and manufactures construction site technology not only for traditional applications but also for the challenges of modern construction sites, making construction better, faster, and more economical worldwide.

Technical Data

| D20 |

Flow Rate: | Standard approx. 20 l/min (depending on transport and mixing shaft) |

Drive Motor: | 2,2kW, 230/400 V, 50Hz |

Electrical Connection: | 230/400V, 50Hz, 1/3pH |

Fuse: | 16/10 A |

Power Cable: | 3 x 2,5 mm²/5 x 1,5mm² |

Plug: | Schuko/16 A, 5p, 6h |

Water Connection: | 3/4" water hose with GEKA coupling, required water pressure: min. 2.5 bar during operation |

Dimensions: | approx. 1700 x 700 x 1,000 mm |

Weight: | approx. 90 kg |

You can download our brochure as a PDF here.

m-tec® Continuous Mixer D30: A Robust All-Rounder for Your Construction Site

An overview: The m-tec® D30 is a robust all-rounder specifically designed for processing dry mortar products with grain sizes up to 6 mm. As a proven tool on construction sites worldwide, the D30 streamlines applications such as masonry work and the processing of fine concrete and screeds.

Applications: Ideal for a wide range of uses, including plasters and self-leveling compounds, the D30 offers flexibility and efficiency for modern construction projects.

Standard Equipment: The standard package includes the continuous mixer with mixing motor, water pump, water fittings, transport screw, and mixing shaft.

Accessories: Optional accessories such as a filter cover or a cover for the material container are available to enhance the mixer's versatility and durability.

Key Features and Benefits:

- Portability: The D30 features a mobile and easy-to-transport design.

- Powerful Motor: Equipped with a 4.0 kW motor, the D30 can handle even tough materials with ease.

- Ease of Use: Assembly and disassembly of individual parts and operation from one side make the D30 simple and convenient to use.

m-tec® – Technology for Better Building: m-tec® develops and manufactures construction site technology for both traditional and modern construction projects. With our technology, used in almost 100 countries worldwide, we make construction better, faster, and more economical.

Technical Data

| D30 |

Flow Rate: | approx. 30 l/min (depending on transport and mixing shaft) |

Drive Motor: | 4,0 kW, 400 V, 50 Hz |

Electrical Connection: | 400V, 50Hz, 3pH |

Fuse: | 16 A |

Power Cable: | 5 x 1,5 mm² |

Plug: | 16 A, 5p, 6h |

Water Connection: | 3/4" water hose with GEKA coupling, required water pressure: min. 2.5 bar during operation |

Dimensions: | approx. 1970 x 690 x 1077 mm |

Weight: | approx. 220 kg |

You can download our brochure as a PDF here.

m-tec® Silo Mixer D50: Advanced Technology for Efficient Construction

Overview: The m-tec® D50 is an advanced silo mixer equipped with state-of-the-art PU components, enabling economical and efficient operation. Specifically designed for dry mortar products up to 4 mm grain size, the D50 has proven to be a reliable tool on construction sites worldwide. It is especially suitable for processing masonry mortar, insulating mortar, plasters, screeds, and fine concrete.

Versatile Applications: The D50 is ideal for a wide range of uses, including:

- Masonry Mortar

- Cement Plaster and Self-Leveling Cement Screed

- Concrete and Fine Concrete

- Decorative Plasters and Fine Plasters

- Screed and Grouting Mortar

- Lime-Cement Plaster, Lime-Gypsum Plaster, and Dry Clay Products

- Renovation Plasters and Self-Leveling Products

Areas of Application: The D50 is widely used in various fields of construction chemistry, from coatings and flooring to masonry, insulation, plastering, and renovation work.

Recommended Accessories:

- Mixing Shaft and Transport Screw

- Flow Meter

- Cover for the Material Container

- S40 Control Cabinet

- Blow-Out Device

m-tec® – Technology for Better Building: m-tec® develops and manufactures construction site technology for both traditional and modern construction projects. With our innovative products, which are used in almost 100 countries, we have made construction better, faster, and more economical.

Technical Data

| Flow Rate | approx. 50 l/min (depending on transport and mixing shaft) |

| Drive Motor: | 4, kW, 400 V, 50 Hz |

| Electrical Connection: | 400 V, 50 Hz, 3 ph |

| Fuse Protection: | 16 A |

| Power Cable: | 5 x 1,5 mm² |

| Plug: | 16A, 5p, 6h |

| Water connection: | 3/4" water hose with GEKA coupling; required water pressure: min. 2.5 bar during operation |

| Dimensions: | approx. 2100 x 350 x 350 mm |

| Weight: | approx. 140 kg |