Automation

MIDAS by m-tec®: Full Control Over Your Production Process

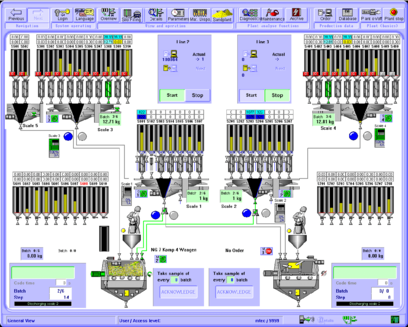

State-of-the-Art Control Technology: MIDAS represents the latest generation of m-tec® control technology, offering a complete hardware and software solution designed to precisely manage and monitor your production processes. This system provides a cutting-edge solution for all your monitoring and control needs.

Customizable Modules for Optimal Performance:

- Modular Design: The MIDAS software consists of individual modules that accurately replicate the actual processes of your production. These modules can be customized and installed to ensure optimal efficiency and accuracy.

- New Dosing Algorithms: Advanced programming in high-level languages allows the new algorithms to achieve even more precise control.

- Dynamic Filters: Specially developed filtering techniques improve the accuracy and reliability of weighing signals.

Enhanced Monitoring Capabilities:

- Visualization and Animation: A detailed representation of processes on multiple monitors with animation facilitates precise monitoring of the plant.

- Full Connectivity: The client/server architecture enables unrestricted data access, regardless of your location.

Flexible Integration and Adaptation: The modular design of the MIDAS control system allows for flexible adaptation to changing production conditions and offers expansion options that seamlessly integrate into your production environment.

The Future of Production Control: With extensive expertise in preparation, dosing, weighing, and mixing, m-tec® is setting new standards for precision and efficiency in production control.