Silo Mixing Pumps 4.0

The m-tec connect machine monitoring system has already made a name for itself in the field of m-tec silo mixing pumps. The m-tec connect machine monitoring system is becoming increasingly established for both silo mixing pumps for plaster processing and for liquid screed. The process technology for these silo mixing pumps remains unchanged and continues to offer simple operation, consistent material quality without fluctuations and infinitely variable output control.

The implementation of m-tec connect machine monitoring only requires the installation of a specially programmed m-tec modem including an antenna for location determination and data transmission. During machine operation, the m-tec modem requests relevant parameters from the machine control system. This data is then transmitted to the m-tec connect cloud, where it is processed and visualized.

Machine Data

In today's machine technology, there is a lack of operational status information during active operation, or diagnostic information when failures and downtime occur, because the data is inaccessible, even if it exists. This has now come to an end.

With m-tec connect Machine Monitoring, machine status is recorded regularly and continuously by measuring and analyzing various machine parameters. Sensors record various metrics that provide insight into the general condition of the machine and its components. Increased machine efficiency, predictive maintenance, detection of incorrect machine operation, continued operation despite faults and remote troubleshooting are just some of the possibilities that m-tec connect Machine Monitoring offers you and your company.

m-tec connect Machine Monitoring is an essential prerequisite for entering the world of Construction Site 4.0 and ensuring the future competitiveness of your company.

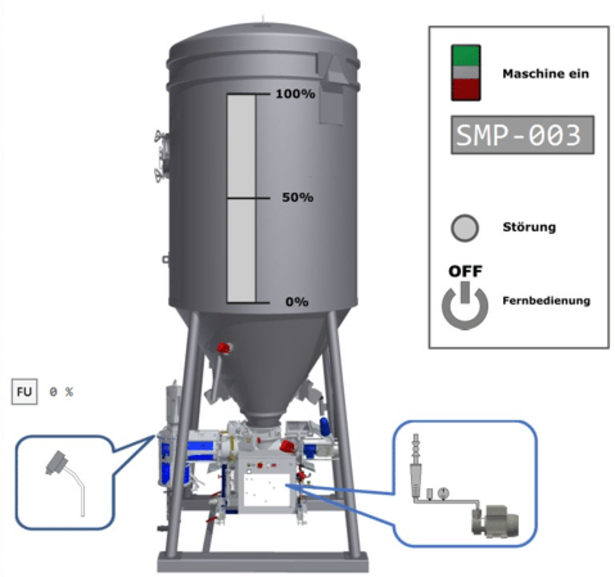

Each machine type has individual parameters that are displayed in the m-tec connect Cloud by m-tec connect Machine Monitoring. All measurable and collected parameters are displayed in a tabular overview, while selected parameters can also be visualized graphically. This includes the error code display, which is shown in a graphical machine overview, as well as the current flow and required water levels for the silo mixer pump product line.