Fill Level Measurement

Gone are the days when your workers needed a rock or a hammer to determine how much material was left in the silo. Today, a smartphone is all you need on a modern jobsite to display the fill level at any time. There's no need to order too much or too little material. Expensive downtimes and time pressure are a thing of the past.

The m-tec connect® silo probes measure the level of material in the silo and enable efficient management of your silos. Dispatchers are always informed about the filling levels of the silos and can organize refills efficiently. Route planning can be optimized according to requirements and unnecessary empty runs are avoided. The m-tec connect® silo probes not only calculate the current material quantity, but also estimate possible refill quantities in the silo.

We offer the ideal probe for your application and silo size. Whether radar or ultrasonic technology, with data transmission and visualization in the cloud or a display unit directly on the silo, we provide the technology that best suits your application.

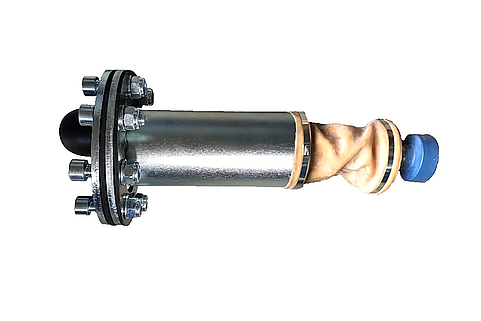

Silo Probes

The m-tec connect® silo probes use the latest ultrasonic or radar technology and offer precise measurements, robustness and intelligent energy management.

Users can adjust the settings for measurement and reporting intervals as required.

The collected level data can be visualized and made available through various options:

- m-tec connect® Cloud

- Display unit directly on the silo

- Interface for data transfer to an external system

Level Measurement

The m-tec connect® silo probes measure the material level in the silo at individually adjustable time intervals. The collected data is visualized in the m-tec connect® cloud both in a tabular overview and as a graphical fill level trend. This provides you with a continuous overview of the periods during which material was removed and refilled. In addition to the fill level trend, you can also display the prevailing temperature in parallel.

All of this data can provide insight into material misprocessing at low temperatures, the use of foreign material, and material withdrawals despite downtime requirements.

GPS-Tracking

Each m-tec connect® silo probe is equipped with an integrated GPS tracker that determines the exact location of the silo. This position is visualized on a map within the m-tec connect® cloud, with color-coded indicators representing the fill levels. This feature provides a quick overview of all your silos, facilitates efficient route planning and minimizes unnecessary travel.