m-tec® Mixers: Proven Quality and Adaptability

m-tec® Mixers: Proven in Practice and Highly Adaptable

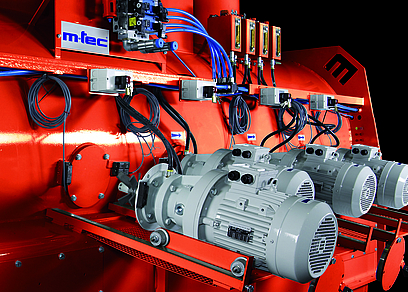

m-tec® mixers have demonstrated their reliability in practical applications for decades. The special design of the mixing tools promotes a three-dimensional movement of the components, enabling high mixing quality in a short time. These mixers offer:

- Adaptability: Mixing tools and drive power are optimally matched to the specific material. Low-wear special blades ensure intensive yet gentle mixing.

- Efficiency Improvement: High-speed agitators with specialized mixing tools introduce additional mixing energy, making it easier to break down agglomerates and mix pigments or fibers.

- Ease of Maintenance: Mixing arms are connected to the mixing shaft via screw-on plug connections, allowing quick adjustments and easy replacement of mixing tools.

Discharge Mechanisms:

- MS Spout Discharge: Suitable for applications where quick discharge is not a priority.

- ME Single-Flap Mixer: Designed for fast discharge processes.

- MR Double-Flap Mixer: Optimal for fast and residue-free discharge.

Specifications:

- MD Continuous Mixer: Ideal for continuous processes and suitable for all types of dry, moist, powdery, and coarse-grained bulk materials.

- Volume Range: m-tec® mixers are available with useful volumes ranging from 11 to 11,000 liters, with additional sizes available upon request.

- Material Options: Depending on requirements, mixers are made from standard steel, stainless steel, or wear-resistant special steel.

m-tec® mixers are not only proven in practice but also deliver high and consistent mixing quality, even with extreme mixing ratios of up to 1:100,000.

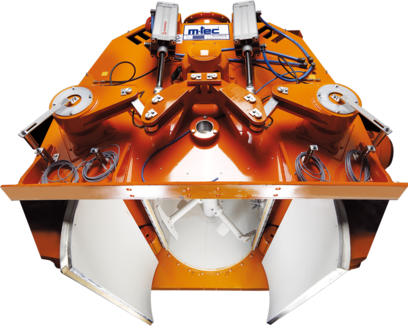

m-tec® MR Mixer – Efficient and Innovative Discharge

The m-tec® MR mixer is renowned for its efficient and innovative discharge system. Two wide discharge flaps, spanning the entire length of the mixer, enable quick emptying of the contents into a buffer container. Only minimal residue remains in the mixer, which can be further reduced by an optional automatic cleaning system.

Advantages of the Discharge System:

- Dustproof and Low-Maintenance Design: Ensures easy handling and durability.

- Time and Energy Savings: The fast discharge significantly increases mixer capacity.

- Continuous Production: While the product is being discharged, a new batch can begin mixing immediately.

Technical Highlights of the MR Type:

- Extremely Short Discharge Times: Around 5 seconds, minimizing the need for manual cleaning.

- Gentle Product Mixing: Achieved through specially designed blade geometry.

- Cost-Effectiveness: Low energy consumption with efficient production.

- Adaptability: Suitable for nearly all dry material mixing tasks.

Special Sealing Technology:

The mixers feature high durability in the mixing shaft seals, supported by a specially designed lip sealing system. An air gap seal is also available upon request.

For More Information:

Download our brochure as a PDF

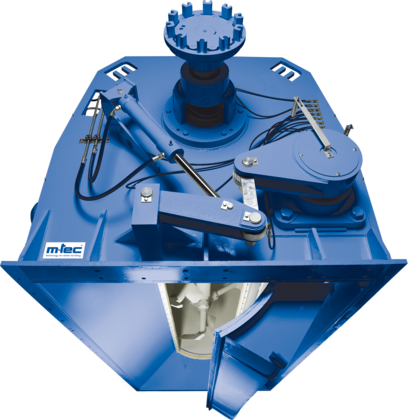

Innovation in Mixing Technology: m-tec® ME Mixer

Unique Discharge System: The m-tec® ME mixer is distinguished by its patented toggle lever system for driving the discharge flaps. This system ensures mechanical locking of the flaps and prevents unintended opening, even in the event of a pressure failure. The high opening speed allows for complete discharge in approximately 10 seconds, significantly accelerating production cycles.

Patented Sealing System: m-tec® has developed a sealing system with excellent self-cleaning properties that prevents material compression at the sealing points. This ensures flawless operation even with products that have high residual moisture. Additional advantages of this system include the long lifespan of the specialized elastomers used and the low maintenance costs made possible by the segmented design.

Advantages of the ME Mixer:

- Fast Discharge Times: Approximately 10 seconds due to high opening speed.

- Reduced Load on Conveying Systems: Quasi-continuous production allows for smaller-sized conveying systems, improving efficiency.

- Gentle Product Mixing: The specially designed blade geometry ensures gentle mixing of ingredients.

- Cost-Effectiveness: Low energy consumption and easy installation as a retrofit system increase profitability.

- Versatility: Suitable for almost all dry material mixing tasks.

For more information, download our brochure as a PDF .

m-tec® MS Mixer: Cost Efficiency and Performance

The m-tec® MS mixer is ideal for cost-conscious customers who rarely change formulations and are comfortable with manual cleaning. Despite its attractive price, this mixer delivers results comparable to our top-of-the-line model, the MR.

Key Features of the MS Mixer:

- Discharge System: Pneumatically operated discharge flaps with spout discharge ensure near residue-free emptying. An optional rectangular flap system further increases efficiency.

- Sealing System: A mechanical self-cleaning system guarantees 100% sealing, even with cohesive mix materials.

- Sealing Technology: High durability thanks to a specially designed lip sealing system. Conventional stuffing box or air gap seals are also available upon request.

Advantages of the MS Mixer:

- Low Investment Cost: Provides a cost-efficient alternative to other models.

- Excellent Mixing Results: Delivers the same mixing results as our premium MR model.

- Simplified Plant Design: Multiple discharge spouts facilitate easy planning and implementation.

- Quasi-Continuous Production: Enabled through the use of a buffer container, similar to the MR model.

- Gentle Product Mixing: Special blade geometry protects the mix and ensures high quality.

For more information and details, please download our brochure as a PDF here.

m-tec® MD Mixer: Precision and Flexibility in Continuous Processes

The m-tec® MD mixer optimizes mixing processes with an advanced design that guides the material along the entire length of the mixer. A manually or motor-adjustable overflow weir at the outlet allows easy adjustment of the fill level and retention time, even during the mixing process.

Advantages of the MD Mixer:

- Continuous Mixing Process: Achieved through a paddle blade mixing system that delivers excellent mixing results.

- Adjustable Operating Conditions: Variable fill level and retention time thanks to the adjustable overflow weir.

- Efficient Discharge: The overflow weir also facilitates the discharge of the mixer.

- Maintenance-Friendly: Easy maintenance and long service life due to its robust construction.

- Practical Design: Low overall height and easy installation as a retrofit system, offering flexibility in existing production lines.

For more information about the MD mixer and its application benefits, please download our brochure as a PDF.

System Solutions for Practical Mixing – From m-tec®, All in One!

m-tec® offers the perfect recipe for ideal mixing: innovative and practical mixing systems for both batch and continuous operations, designed for a variety of industries. The focus is always on achieving the highest mixing quality.

Technology Highlights of Our Mixers:

- Paddle Mixing Systems: These systems are particularly gentle on products while being highly efficient.

- Additional Tools for Special Requirements: For hard-to-break materials like agglomerates or for mixing pigments and fibers, we use high-speed, independently driven agitators.

- Adaptability: Depending on your needs, air-gap agitators or mechanical seal agitators are available and can be controlled with compressed air.

Application Flexibility:

Every m-tec® mixer comes equipped with connection flanges as standard, allowing whirlers to be easily retrofitted if they are not already integrated.